No Line on the Horizon

From left: John Lin, owner of the refurbished 1966 Airstream Caravel trailer, and furniture maker Owain Harris Renovating an American classic requires a mission, a plan and a few curves.

Owain Harris was first drawn to woodworking by the problemsolving challenges inherent in the work.

“I tend to be attracted to, some might say, overly complex things,” Harris says. “But that’s what keeps it interesting to me. I’d go out of my mind if I was building the same thing over and over.”

That’s good, because when a 17-foot, 1966 Airstream Caravel trailer with aspirations of becoming a seasonal home was towed to his workshop on an August day a few years ago, it became clear fairly quickly there would be problems that needed solving.

Airstreams were first built in the 1930s—iconic, now, and easily identified by their distinctive round shape and polished aluminum exteriors. Harris was tasked with turning the travel trailer into a space that could function as an office, a reading sanctuary and a guest bedroom. It would become a summer home on Lake Winnipesaukee. Simple enough on paper. But in practice, the challenges would quickly reveal themselves—specifically, the Airstream’s contoured interior.

“It’s fascinating from a construction standpoint,” he says. “There’s no horizon line. You have to invent a horizon line because it can be arbitrary. The floor is flat, but it’s not level because it’s up on tires. You level the floor, but then you need to establish benchmarks you build everything off of, which is so different from building a house.”

Given the iconic status of the Airstream, Harris knew he would have to get every detail right. And while there was a bit of pressure, the distinctive shape, singular contours and quirky bends of the trailer’s design provided plenty of inspiration when it came time to make design decisions.

The Airstream Caravel arrived at his Deerfield workshop gutted, with the frame repaired, a new subfloor bolted to the aluminum shell, new windows and a new air conditioning unit. From the builder’s perspective, it was a blank slate.

“[The owners] bought it in California, I believe, and had gone out, picked it up and done a road trip, living in it on the road as it was originally configured,” Harris says. “It was in fairly decent condition—and a little intimidating, to be honest. In retrospect, I wish I had them keep the wall panels [the Airstream came with], if for no other reason than to have a template to make the wooden ones. That ended up being the most time consuming and complex part of the project.”

But first: a floor plan. Harris brought in his friend and collaborator Aimee Brothers, of Lavender and Lotus Interior Design.

The curving contours and distinct character of this classic Airstream provided plenty of inspiration for craftsman Owain Harris.

“I felt pretty early on in the project that the success of fulfilling the brief in terms of what the clients wanted to use the space for relied heavily on the layout and where we would put things,” Harris says. “It’s such a small space, and they specifically wanted a desk, a coffee stand/kitchenette type thing, to be able to sleep three people, a reading area and a storage closet. Cramming that into a 17-foot space is a lot, so I felt like it made a lot of sense to bring in somebody who is good at manipulating space and getting the most out of it.”

Then, the walls. The rounded form meant he’d be working in a familiar but challenging format.

“A lot of my designs feature technique-heavy aspects—a lot of bent, laminated work,” he says. “Four or five years ago, I bought a CNC [computer numerical control router machine] and integrated that into my process.”

Harris maneuvers a sycamore door with walnut trim into place.

For the Airstream project, all the studding had been stripped out during the preparation process. So, Harris had to create studs that would allow for wiring chases and a wall panel. Starting with a three-eighth-inch layer of bending plywood, he built laminated studs in place, using the curves of the trailer as the mold. Harris used a combination of polyurethane glue and hot melt glue to hold it in place. Each layer was glued and screwed down, building out to the required thickness.

Designer Aimee Brothers of Lavender & Lotus Interior Design collaborated with Harris to create an efficiently designed, bright space, which provided room for a foldaway table and a banquette that folds out into a double bed.

With wiring and a layer of fiberglass insulation in place, Harris turned his attention to the walls themselves. Rather than create a scale model to craft panels and then install them, he opted to bend them in place. He followed the compound curves using wedges of one-eighthinch, bending poplar to replicate the same technique used for the aluminum skin on the outside of the trailer. Each section was butted up against the previous, with walnut strips over the seams.

The cabinetry, a much more familiar and comfortable world for Harris, was built of Baltic birch plywood with sycamore veneer and walnut trim—first the kitchen area and then over the writing desk.

“I suggested sycamore to help keep the interior brighter,” he says. “It’s a small space, and there’s so much in there.”

The dark details of the walnut desk are reflected in drawer and door pulls that were in turn inspired by the curvature of the trailer. Harris says the flat design, with an elliptical-shape cutout inspired by the Airstream’s rounded edges, reduced the chance of someone snagging clothing while moving around the cozy interior.

Harris designed the banquette and a built-in bench, and turned his attention to a complicated 7-foot-tall corner closet—again, curved. Weight was an ongoing issue, and the closet was ultimately crafted from a lamination of five one-eighth-inch pieces of plywood with a sycamore veneer. He called on the skills of Bob Rielly for paint and cabinetry finish, and Deborah Fisher for upholstery and cushion work.

Step up into the finished Airstream, and you’re facing the banquette, which runs under a window and folds out into a double bed.

“That ended up being an engineering nightmare,” Harris says. “Everything is curved, and having something that could slide out and fold out, and have the structural integrity to support people sleeping was a real headscratcher.”

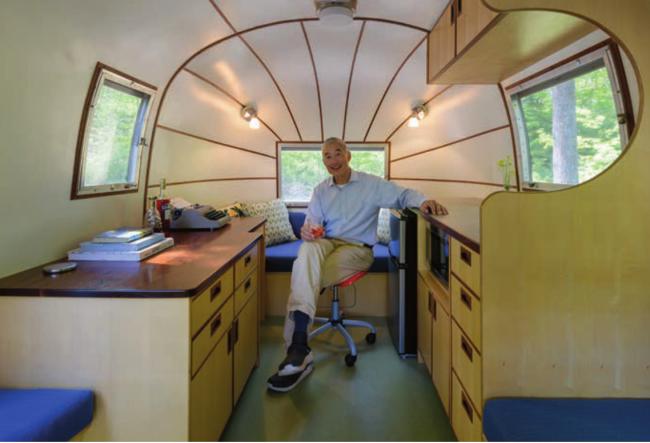

John Lin gets comfortable in the renovated 17-foot Airstream, which serves as a cozy summer sanctuary.

Just to the right: the tall storage closet. An end table divides the two with a mirrored medicine cabinet above it. Inside the bedside nightstand is a table that folds out—original, but adjusted for the newly built top. To the left is a curved seating area with an upholstered top and storage below. Turn to the left again, and the desk runs nearly to the end of the trailer. On the right, there’s a partition wall between the end of the banquette and storage cabinets, a counter and more storage that terminates at the day bed/reading nook at the back of the trailer. “Perfect for sitting and contemplating the lake,” Harris says.

Harris finished the Airstream off by covering the panel seams throughout with strips of walnut—strong enough to hold the panels, but thin enough to follow the curvature of the trailer—and held them in place with decorative oval head screws.

All the benches and the main banquette feature storage underneath, accessed through the base of the bench. There, Harris took the opportunity to incorporate some of the trailer’s original hardware, completing the marriage of old and new, and answering perhaps the final query the 1966 artifact posed.

“It seemed like a really interesting project from the beginning,” Harris says. “Frankly, it’s not every day someone asks if you can do an Airstream interior. I really enjoy curved projects. A lot of my work is bent laminates and veneer work. I met with the clients, we hit it off, and I think their vision matched my aesthetic interest.

“And, crucially, they weren’t in any huge rush. I knew it was going to take some time, and I was going to have to figure a certain amount of things out. I knew it was going to involve bringing other people in. If [the clients] told me they needed it in six months, I would have had to say no. They were willing to be patient.”

A year of work went into the laborintensive project, chipping away at new phases and encountering new (and fascinating) challenges. As for keeping track of estimated hours: “I tend not to do that. Some projects you do because you’re excited and you think it’s going to be fun; some you take to make money. This project was the former.” That is what made the Airstream project perfect for this juried member of both the New Hampshire Furniture Masters and League of New Hampshire Craftsmen.

“Projects like this, I try not to think about how complicated it’s going to be,” he says. “But, at a certain point, I have to dive in and figure it out. It’s that way with most of the projects I’ve enjoyed and gotten the most out of personally and professionally.” NHH

RESOURCES

Debbie Does Divans • (603) 363-4339 debbiedoesdivans.com

Lavender & Lotus Interior Design • (603) 496-2606 lavenderlotusdesign.com

Owain Harris • O.H. Harris Furniture Maker owainharris.com